” We are a medium-sized slaughterhouse. Our philosophy involves working transparently and developing our business and way of thinking every day. “

” Our operation is based on two core principles: Produce excellent meat quality and outstanding products for our customers and partners daily. We also deeply value respect for people, the animals in our business, and the environment. As an entrepreneur, I am committed and dedicated to my business, the industry, and the region. “

The history of Brand quality meat

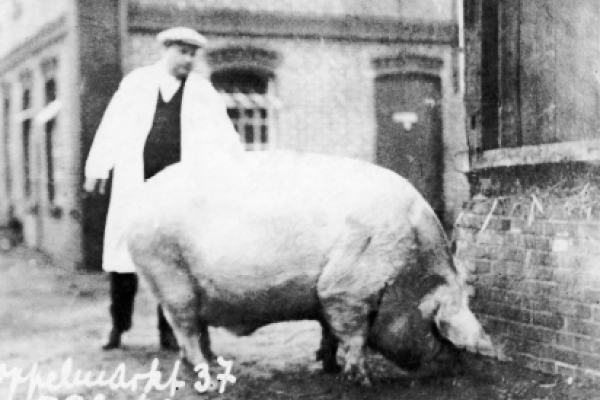

Founded in 1930 by Paul Brand I (grandfather of the current managing director), and now managed by the family’s third and fourth generations, Brand Qualitätsfleisch has continually developed an innovative, increasingly modern face over the years. The entire history of the company is characterized by innovation, optimization, and the desire to become even better.

The company’s roots trace back to the former site of a straw hull factory. As one of the first meat companies in Germany, Brand Qualitätsfleisch, with the emerging possibilities of refrigeration technology, no longer transported animals to the live markets in the big cities. They instead performed their own slaughtering, with short transport routes within the production itself, and final meat products shipped to the customer.

|

1958

Paul Brand II, son of the company founder, becomes the new managing director. Start of meat and sausage product production following the Second World War in 1945. Dispatch slaughtering of pigs starting in 1951.

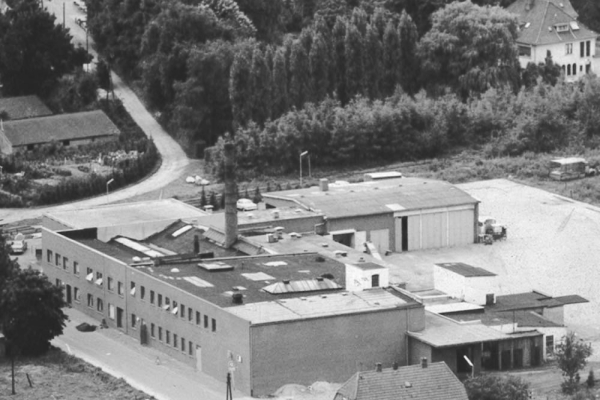

The increase in the number of fattening pigs in the region led to a rapid production expansion, which was reflected in 1958 with the modernization of the slaughtering plant and the expansion of the cooling facilities. Ten years later, a new slaughterhouse was built that featured the first belt slaughter facility.

|

1989

Paul Brand III takes over company management in 1979. In 1981, with the extension of the pig cutting plant, the foundation stone is laid for the partnership with the company Schmitz GmbH as a cutting plant, which commenced operations in 1983. Addition of new loading ramp and a further extension of the cold storage and deep-freeze rooms.

In 1989, Brand was the first slaughterhouse in Lower Saxony to introduce the system of gentle CO2 anesthesia. This method originated in Denmark.

|

2006/7

Commencement of operations of one of the most modern German slaughter lines in the newly-refurbished slaughterhouse. For the first time in Germany, a special steam condensation brewing plant is installed in a slaughterhouse of this size.

In 2001 Brand joined QS (quality and safety) as a founding member. The Butina Backloader, the most modern CO2 plant in the world, complete with fully electronic sensor controls, was installed in the summer of 2003. New cold storage with fully automated infeed and outfeed conveyors (target control), automatic stack conveyors, and new loading ramps were added in 2006/2007.

Creation of the first special Duke of Berkshire value chain program, laying the foundation for the long-term development of a variety of new value chains.

In 2019, these programs featuring modern, species-appropriate animal husbandry, special breeds, and transparent communication were integrated into the Brand Meat Excellence concept and, thanks to increasing demand, are now an important pillar of the company.

Founding of the Open Stable Club.

Together with farmers, scientists, and at the request of the company Bedford (Osnabrück, Germany), the Open Housing Association for the Promotion of Open Housing of Pigs e.V. was founded. As one of the founding members, we continue to promote the ideas of the association with our partners and have enjoyed steadily growing interest and membership since its foundation.

Niko Brand, now the 4th generation of the Brand family, has taken over additional roles from Paul Brand III, and is moving the company forward with innovative ideas. Niko Brand expands the business with a new hall featuring a state-of-the-art cutting facility to meet the requirements of complex special marketing. It not only effectively performs large-volume standard cuts, but can also quickly and easily handle special orders. The long-standing partnership with the Schmitz company is brought to a successful completion.